Improving the Bottom Line and Environment Through Reverse Supply Chain Logistics

A dozen years ago, Dan Guide was clearing out his parents’ longtime property and found an old rotary phone tucked away in a closet. It was a heavy desktop model in a dull yellow, built to last by Bell Labs. He plugged it in to see what would happen. It worked.

“So, I opened it up,” explains Guide, who is the Smeal Chaired Professor of Operations and Supply Chain Management. “It had a plastic housing, point-to-point wiring, and a physical ringer bell. A technician could bring anything they needed in a box to repair this phone on site. When I went back and read the archived Bell Lab information, it said the phone had an expected life of about 40 years.”

That phone was from a time when a business model, called servicizing, was being used, he says. For example, the phone belonged to Bell, but you paid for the service. Customers paid a very low cost for repair since the phone was designed right from the start with easy repair in mind. If the customer didn’t intentionally damage the phone, it would be replaced at no cost. Other manufacturers of major equipment use this model too, like office copiers (pay by the page), airplane engines (pay by the mile), and locomotive components (time-based pay, aka “power by the hour,” as it’s called in the industry).

Around the same time, Guide noticed a white iPhone on a student’s desk — even though she already had the black version. When he asked about it, she said, “The white one became available yesterday, so I got it.”

“We’ve had a profound impact on our planet through industrial activities. But I don’t think we can put the genie back in the bottle,” explains Guide, who joined Smeal in 2002 and also serves as the college’s Supply Chain and Information Systems Ph.D. program coordinator. “We’ve created a consumeristic society with business models based on buying.”

The two phone examples demonstrate critical parts of Guide’s longtime expertise in closed-loop supply chain management, the study of a product’s lifecycle. The first shows how some businesses can maximize the value of their products over the long-term using approaches like remanufacturing. The iPhone story shows how consumers have responded to changing business models.

Guide has spent his career working with industry to create closed-loop supply chain management systems that are environmentally and economically sustainable. His solutions allow companies to build value in a product throughout its lifecycle. It’s a process called reverse logistics that begins with product design, creation, and delivery (supply chain management) and then back again to the manufacturer or supplier (reverse supply chain logistics) to be fixed, remanufactured for resale, or recycled for parts or materials that can be used in other products instead of being tossed into a landfill.

Expertise and practical application

In 2017, Guide was listed as the leading reverse logistics expert in an International Journal of Physical Distribution & Logistics Management research study. The analysis showed that papers about reverse logistics with Guide as an author were cited 451 times by 34 other studies, making him the world’s most cited author on the topic. A prolific researcher, Guide has written more than 100 papers on supply chain, reverse logistics, and other related topics. On Google Scholar, his works have been cited 16,850 times. He has also developed a course at Smeal focused on the sustainable supply chain, which includes reverse logistics.

“We’ve created a consumeristic society with business models based on buying.”

Guide’s work has earned him numerous honors. In 2014, he was appointed the Smeal Chaired Professor of Operations and Supply Chain Management for his research accomplishments. There is only one Smeal Chair per department. He has also been named a Production and Operations Management Society Fellow in 2019 and a Distinguished Scholar by the Academy of Management, Operations, and Supply Chain Management Division in 2018. From 2011 to 2017 he served as co-editor-in-chief of the Journal of Operations Management.

“Dan takes an engaged scholarship approach to research by working directly with supply chain logistics practitioners in industry to identify their more challenging problems and develop academic research questions around that,” says Kevin Linderman, chair of the Department of Supply Chain and Information Systems and John J. Coyle Professor in Logistics and Supply Chain Management. “He then provides them with insights into how to better manage their organization.”

Linderman adds that Guide was an early expert in reverse logistics.

“Whenever we talk about sustainability in the supply chain, it typically involves some form of reverse logistics,” he says. “As consumers increasingly buy online, the ability to effectively handle returns and reverse logistics becomes more important.”

“He’s one of the world’s experts in the circular supply chain,” says Steve Tracey, executive director of Smeal’s Center for Supply Chain Research, noting that the process of bringing value back to a product by remanufacturing it and making it better than before is Guide’s core expertise.

The importance of closed-loop systems

“I think we’re staring down an environmental nightmare, with air pollution and water levels rising,” says Guide. “We’re going to run out of some rare earth elements at a certain point.

“But you can’t tell a company to adopt a business model that doesn’t make them money,” he continues. “In the 1990s, we used to try to talk about the environment and some of these executives’ eyes would glaze over.”

He suggests people stop talking about environmental benefits and instead ask companies if they would like to make more on their bottom line. If the product is designed from the start to be remanufactured, reused, or repurposed, it will continue to deliver value after it is returned.

“I think we’re staring down an environmental nightmare with air pollution and water levels rising.”

“That actually gets people’s attention,” he says.

A key hope for the future is the evolution of the digital supply chain. Instead of manufacturers making spare parts that are stored in large warehouses, those components can be made on demand using additive or subtractive manufacturing systems. All that needs to be shared is the digital engineering design file. (Additive manufacturing equipment like 3D printers lay down layers of material to build the item. Subtractive machines grind, cut, or drill into a block of raw material such as plastic, metal, or other materials to create the part.)

“Right now, these approaches are not mainstream,” Guide says, noting the economics of such approaches are becoming more pressing. “The advantage is these can allow on-demand and just-in-time production of parts.”

He cites the example of a cargo ship that was prohibited from leaving the port of Singapore because a 20-year-old emergency on-board communication system wasn’t working. A cheap plastic part broke, and no replacement was available. To avoid staying in port at a cost of about $30,000 a day, Guide says, “they scrapped the old system and put in a new one with $20,000 worth of equipment—all because they couldn’t get a $1 part.”

However, if there was a digital blueprint for the part, it could be ordered on demand from an additive manufacturing center.

“If the part is co-located at the port, I just walk it over to the ship. I don’t have to air freight it from some remote warehouse.”

Not a solo pursuit

Of his career, Guide says he has been fortunate to work with so many fantastic and talented Ph.D. students, co-authors, mentors, and colleagues over the years.

“I always like to stress that if you look at all of my research in the publications, there are a bunch of other names there with me,” he notes. “I might have been better at herding people and pushing things, but it’s all been a team effort. It’s been wonderful to work around people who are really smart. That makes the difference.”

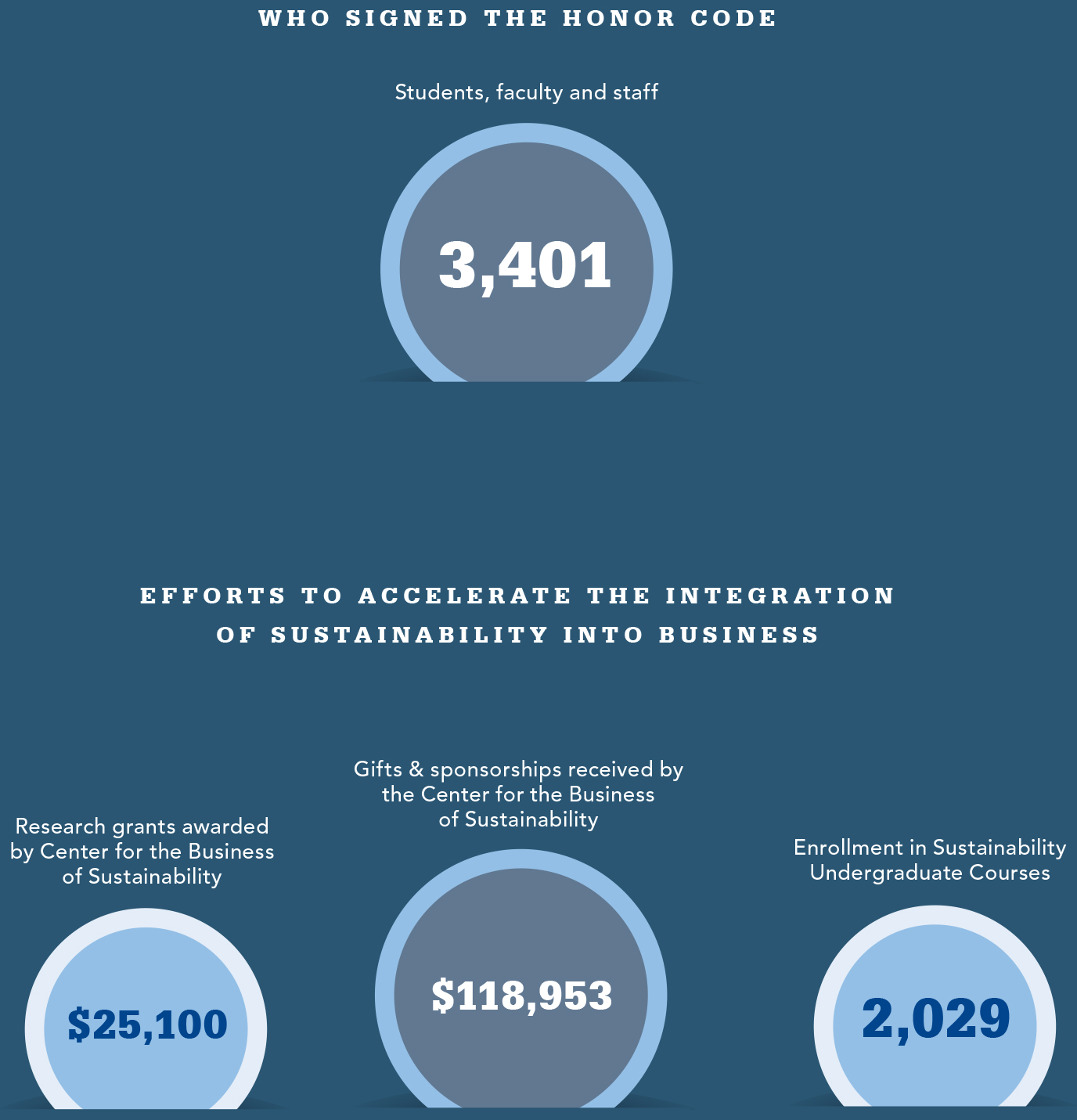

Smeal By the Numbers

How Smeal worked to make business better in 2021-22: